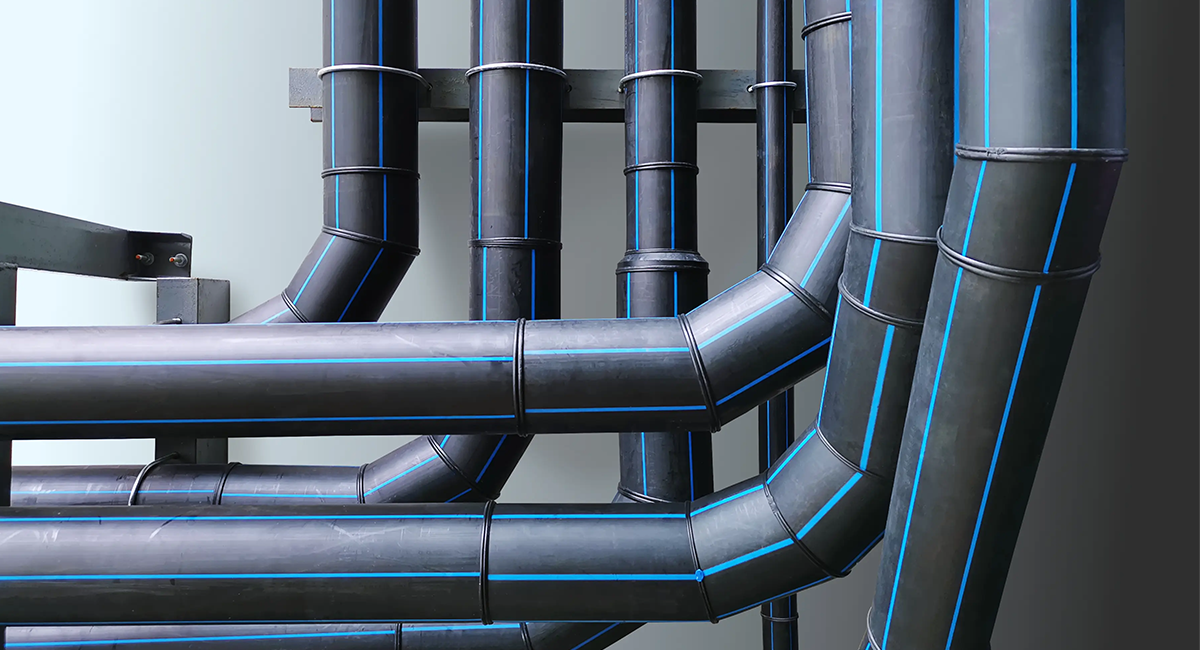

HDPE Pipes

HDPE pipes have unique qualities of being both tough and have a long life span, due to its high chemical and abrasion resistance properties. They are rapidly growing as the preferred material for the mining industry.

This includes pipeline lining and relining, slurry applications, sewer and stormwater systems as well as cable conduits.

The main applications of HDPE Pipes could be summarized in few points

- Water Transportation

- Distribution of Energy

- Discharging Waste Water

- Telecommunications Systems

Key Benefits of Polyethylene Pipes

Our latest factory on the 10th of Ramadan, Cairo is equipped with the most up-to-date machinery and equipment in Egypt. Which produces 40,000 K Tons (HDPE) annually. Offering a wide range of HDPE pipes & fittings according to the global quality standards. Seif Al Nasr company offers a wide pipe diameter range from 16 mm up to 1600 mm with different pressure classes from 3.2 bar up to 20 bar. Seif Al Nasr provides a wide range of HDPE fittings up to 1600 mm according to the customer›s request.

Polyethylene pipes are highly resistant to a wide range of chemicals, including bacteria, fungi, and aggressive soils. They do not require cathodic protection, making them maintenance-free throughout their lifespan.

Thanks to polyethylene’s low thermal conductivity, these pipes are excellent at retaining heat, minimizing heat loss, and preventing condensation on their surfaces.

Polyethylene pipes provide an effective barrier against microorganisms and bacteria. Their inner surface prevents harmful contaminants from leaching into water, ensuring safe and clean transport.

With excellent chemical resistance and a non-abrasive surface, polyethylene pipes minimize the risk of deposit formation and surface defects, maintaining superior hydraulic characteristics over time.